As a supplier of TUBU LED grow light, we understand our OEM/ODM customers' extreme pursuit of performance, cost and differentiation. Customizing Quantum Boards is not simply a matter of adjusting parameters, but a precise game involving optics, thermals and engineering. In this article, we will reveal 5 key parameters that determine the success or failure of customization, and help you precisely control the competitiveness of your product.

Optical Efficiency - The “soul Parameter” of Customized Quantum Boards

Optical Efficiency and Spectrum: The Differentiation of Customized Quantum Boards

Optical efficiency (PPF/W) directly determines the cost of energy consumption, while spectral formulations (e.g., full spectrum/red light enhancement) need to match the crop type. Spectral formulation (e.g., full spectrum/red light enhancement) needs to be matched to the type of crop (e.g., marijuana, vegetables).

Beam Angle & Uniformity: The Invisible Battleground for Customizing Quantum Boards

Narrow beam angles (60°) are suitable for vertical cultivation, while wide beam angles (120°) need to be paired with anti-glare designs.

Key action: When customizing Quantum Boards, ask your supplier for an IES light distribution curve simulation report.

Thermal Management - Lifetime Guarantee for Customized Quantum Boards

Thermal Structure: Engineering Bottom Line for Customized Quantum Boards

Aluminum substrate thickness (≥1.6mm) and thermal conductivity gel coefficient (>3.0 W/m-K) are the basic thresholds.

Protection Levels: Environmental Adaptability of Customized Quantum Boards

Humid environments require IP65 waterproof design, and high dust scenarios require anti-static coatings.

Warning: Custom Quantum Boards that ignore thermal management will see failure rates soar by 300%.

Electrical Compatibility - Integration Pain Points for Customized Quantum Boards

Driver Power Supply: The “nerve Center” of Customized Quantum Board

constant current driver (recommended PF>0.95) and dimming interface (0-10V/DALI) need to be confirmed in advance.

Case: A customer did not specify the PWM dimming frequency, resulting in a conflict between the customized Quantum Board and the control system.

Voltage Range: The Customized Quantum Board Is Globally Adapted

wide-voltage design (90-305VAC) can cover 80% of national grid standards.

Size and Modularity - The Industrial Aesthetics of Customized Quantum Boards

Space Utilization: Compact Design of Customized Quantum Boards

With SMD placement technology, the size of Customized Quantum Boards can be reduced to 60% of conventional products.

Trend: Magnetic modular design supports customers to quickly iterate on custom Quantum Board layouts.

Mounting Interfaces: Engineering Convenience for Customized Quantum Boards

Pre-positioned U-bracket holes with airline plugs reduce field deployment time by 30%.

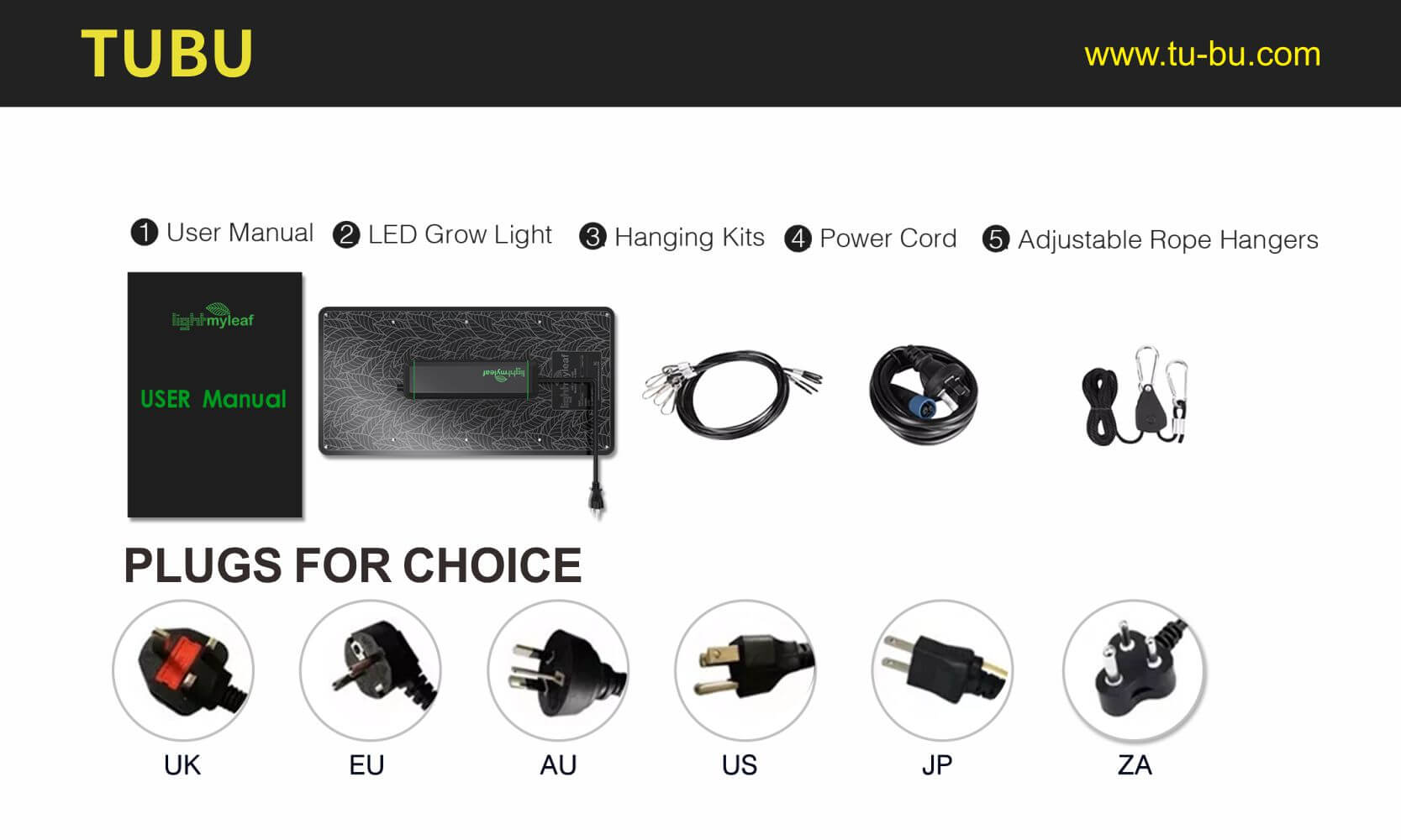

Quantum Board Grow Light

Quantum Board Grow Light

Certifications and Compliance - The Market Pass for Customized Quantum Boards

Safety Certifications: Bottom Line Requirements for Customized Quantum Boards

Certifications: UL/ETL (North America), CE/RoHS (EU).

EMC: The Invisible Threshold for Customized Quantum Boards

FCC Part 15/EN 55015 standards require professional darkroom testing or risk of product recall.

The Ultimate Rule of Customized Quantum Board

Successful customized Quantum Board projects need to form a closed loop in five dimensions: Optical, Thermal, Electrical, Structural and Compliance. TUBU suggests customers to adopt the “Parameter List + DFM (Design for Manufacturing)” dual-track model to avoid falling into the “over-performance”. TUBU recommends customers to adopt the “Parameter List + DFM (Design for Manufacturability)” dual-track parallel model to avoid falling into the trap of “over-performance” or “hidden cost”.

If you have a large demand for customized Quantum Boards, please feel free to contact the TUBU team!