In this paper, we compared the effects of digital seedling production in LED plant factories and traditional greenhouse seedling production on the growth of cucumber in the field. The results show that the digital seedling of cucumber in LED plant factory has the following characteristics: shorten the cucumber fertility cycle by 15~30d; have no significant effect on the length of the main stem of the cucumber plant, the pitch of the node and the weight of the single fruit; increase the number of female flowers and the number of fruits of a single plant by 33.8% and 37.3% respectively; increase the yield of a single plant, especially in the early stage, and thus improve the yield and efficiency of a unit area significantly.

Cucumber is an important economic crop in China, with a cultivated area of about 7.7 million hm2 and an annual output of 60 million t. At present, cucumber seedling nurseries in China are based on the traditional solar greenhouse, and the seedling production process is affected by the environment, and the cost of labor management is high. With the development of photoelectric technology, LED light source with small size, long life, low heat generation and good spectral performance is widely used in plant factories.

In recent years, we have carried out a pilot demonstration of digital seedling nursery of cucumber in LED plant factories in Quzhou. Compared with the traditional nursery method, LED plant factory digital nursery has the advantages of low running cost, no influence from the external environment, short nursery cycle, and neat and strong seedlings.

In this experiment, three demonstration bases were selected in Kecheng District, Quzhou City, to investigate the effect of LED plant factory digitalization on the agronomic traits and yield of cucumber, in order to provide theoretical basis for the large-scale promotion of LED plant factory digital seedling.

Materials and Methods

Overview of the experimental area

Huahua Family Farm is located in Xiajiang Village, Kecheng District, Quzhou City, with loamy soil and medium fertility, and mainly grows peppers, tomatoes, cucumbers, gourds, lettuce, celery, cauliflower, etc.; Bongsheng Family Farm is located in Shangtong Village, Jiuhua Township, Kecheng District, Quzhou City, with loamy soil and medium fertility, and mainly cultivates cucumbers and peppers in its facilities; Seasonal Farm is located in Doumulong Village, Douxie Township, Kecheng District, Quzhou City, with medium fertility, and always grows vegetable crops such as eggplants and melons. The family farm is located in Doumulong Village, Kecheng District, Quzhou City, with loamy soil and medium fertility, and grows tomato, melon and other vegetable crops all year round.

Materials for testing

The cucumber variety for the test is Boxin 5-1, which was cultivated in greenhouses by three farms using hole tray substrate seedlings, and LED light source seedlings were cultivated by Zhejiang Quzhou Zhongheng Agricultural Science and Technology Company Limited using a fully enclosed LED plant factory.

Field survey

The LED plant factory seedlings (hereinafter referred to as LED light source seedlings) and farmers' self-breeding seedlings (hereinafter referred to as conventional seedlings), which were robust and uniform, were selected for planting respectively. The planting of LED light source seedlings in Bangsheng Family Farm was 43.5 cm in spacing and 2m in width, equivalent to 1,533 plants per 667 m2; the planting of conventional seedlings was 36.5 cm in spacing and 2m in width, equivalent to 1,827 plants per 667 m2. Huahua Family Farm LED light source seedling planting spacing is 36cm, border width 2m, discount per 667 m2 planting 1852 plants; conventional seedling planting spacing is 43.5cm, border width 2m, discount per 667 m2 planting 1533 plants. The planting spacing of LED light source seedlings and conventional seedlings of Seasonal Fresh Garden Family Farm is 43.5cm, the width of the bed is 2m, and 1533 plants are planted per 667m2. After planting, all field management measures were the same. Ten cucumbers were randomly selected from two different types of seedling plots to investigate the field traits such as internode spacing, main stem length, number of female flowers and number of fruits. For cucumber yield determination, 10 cucumber plants of different seedling methods were randomly selected, 5 commercial cucumbers were harvested from each plant, and the average fruit weight was measured, and the yield per unit area was calculated according to the planting density and the yield of a single plant.

Results and Analysis

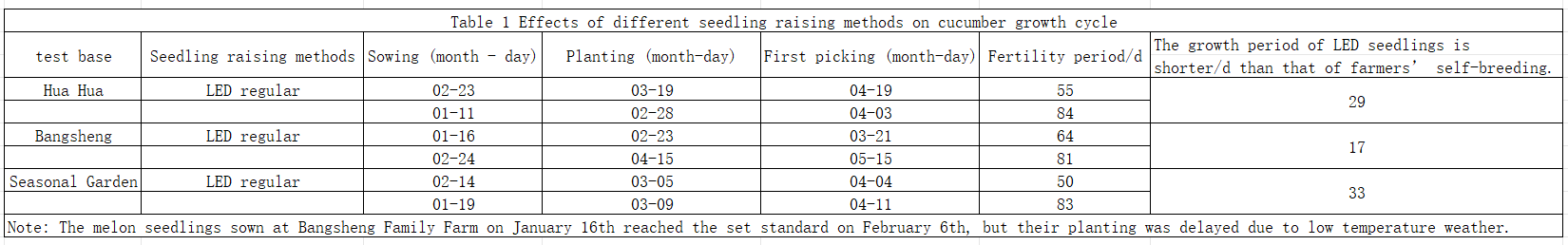

The effect of LED seedling on cucumber fertility cycle

The digital seedling nursery in LED plant factories significantly shortened the fertility period of cucumber (Table 1), in which the LED light source seedlings in Huahua Family Farm and Seasonal Fresh Garden Family Farm shortened the fertility period by 29 d and 33 d respectively compared with that of self-cultivated seedlings, and the fertility period of the seedlings in Bongsheng Family Farm was shortened by 17 d compared with that in the other farms, mainly due to the influence of low temperature, and the delay of LED light source seedlings reaching the standard of planting by about 10 d. The effect of LED light source seedlings on the fertility period of cucumber was mainly due to the influence of low temperature, and the delay of the LED light source seedlings reaching the standard of planting. The main reason was the delay of about 10d after the LED light source seedlings reached the planting standard due to low temperature.

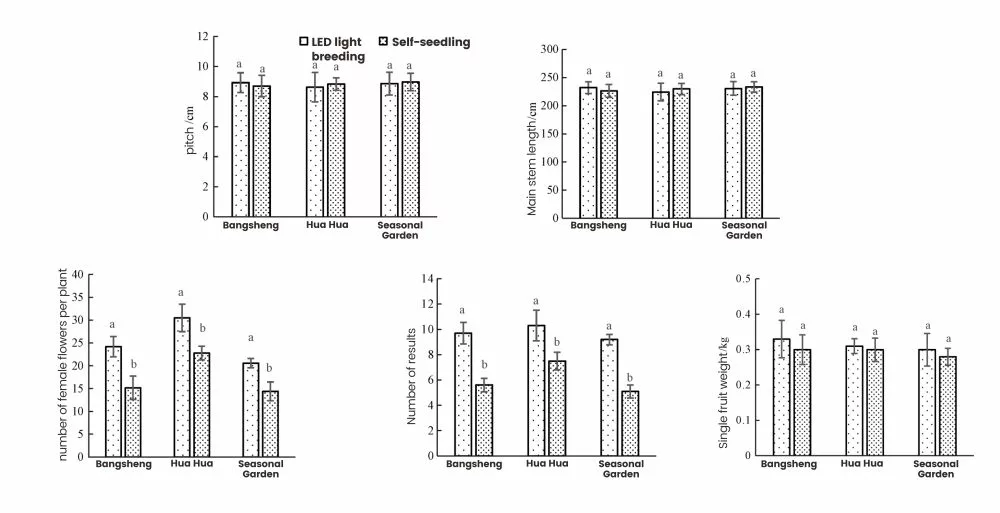

The effects of different seedling methods on cucumber traits in the field

The results of the three experimental bases were basically the same, there was no significant difference between the LED light source seedlings and the farmers' own seedlings in the average internode spacing and main stem length, but the LED light source cucumber seedlings showed obvious advantages over the farmers' own cucumber seedlings in the number of female flowers and the number of fruits of a single plant (Fig. 1). The average number of female flowers and fruits per plant of LED light source cucumber seedlings in Bangsheng Family Farm was 24.2 and 9.7, respectively, which increased the number of female flowers by 7 and the number of cucumber fruits by 4.1 per plant compared with the conventional self-breeding seedlings of the farmers; in the experimental base of Huahua Family Farm, the number of female flowers of LED light source cucumber seedlings was 30.5 and the number of fruits was 10.3, which increased the number of female flowers and the number of fruits by 10.3 compared with that of the conventional self-breeding seedlings. The number of flowers and fruits per plant increased by 7.7 and 2.8, respectively, compared with the number of female flowers and fruits of conventional self-fertilized seedlings. In addition, for the average single fruit weight, the average single fruit weights of LED light source cucumber seedlings in Bangsheng, Huahua and Seasonal Garden family farms were 0.33, 0.31 and 0.30 kg, respectively, which were slightly increased compared with those of conventional farmers' seedlings, but the differences were not significant.

Different lowercase letters on the bars indicate significant differences between groups.

Figure 1 Effects of different seedling raising methods on cucumber field traits

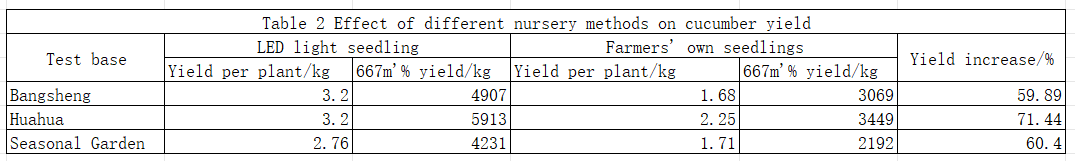

Effect of seedling culture on cucumber yield

Under the same management conditions, the application of LED light source cucumber seedlings can improve the yield per unit area to a certain extent (Table 2), in which the yield of LED light source cucumber seedlings demonstration site of Bangsheng Family Farm was 4907 kg per 667 m2, which increased by 59.89% compared with that of farmers' self-breeding seedlings (3,069 kg), and that of Huahua Family Farm was 5,913 kg per 667 m2, which increased by 59% compared with that of farmers' self-breeding seedlings (3,069 kg). The yield of LED light source cucumber seedlings demonstration site of Huahua Family Farm was 5913 kg per 667 m2, an increase of 71.44% compared with that of farmers' own seedlings (3,449 kg); the yield of LED light source cucumber seedlings demonstration site of Shifuyuan Family Farm was 4,231 kg per 667 m2, compared with that of farmers' own seedlings (2,192 kg), and the planting of LED light source cucumber seedlings increased the yield by 60.40%.

Summary and discussion

The experiment shows that the use of LED plant factory cucumber seedlings for greenhouse cucumber production in winter and spring can not only greatly shorten the cucumber fertility cycle, accelerate the production progress, but also effectively increase the number of female flowers and results of a single cucumber, thus effectively improving the yield per unit area of cucumber, greatly increasing the economic benefits of cucumber production. In addition, He Runyun on the cost of different seedling methods of investigation and research found that the LED plant factory digital seedling with low operating costs, accurate and controllable, neat seedlings and other advantages, has a very broad prospects for the promotion and application.