Introduce

For LED lighting, there are several surface mount device (SMD) types on the market, all identified by a four-digit number, The first two digits indicate the width of the package, while the last two digits indicate its length. These SMD types play a vital role in determining the performance and characteristics of LED lights. Two commonly used ones are SMD 2835 and SMD 3030. For example, the SMD dimensions on a 3030 LED strip are 3.0mm x 3.0mm. In this article, we’ll take a deep dive into the differences between SMD 2835 and SMD 3030, exploring their specifications, applications, and advantages.

What are SMD 2835 and SMD 3030?

What is SMD?

Before we get into the details, let’s first understand what SMD actually is. SMD stands for surface mount device and refers to an electronic component designed to be mounted directly to the surface of a PCB. SMD components, including LED lighting fixtures, are widely used in various electronic devices.

SMD LEDs are small light-emitting diodes that can be mounted directly to a PCB without leads or wires. They are known for their compact size, high brightness, and energy efficiency.

What is SMD 2835

The SMD 2835 is a rectangular LED chip measuring 2.8mm x 3.5mm. It is a single-chip LED package, which means each unit contains only one LED chip. LED lighting products often use such chips because of their high performance, efficiency, and affordability. It is trendy in LED strips, light bulbs, and other lighting fixtures that require large numbers of small, efficient light-emitting diodes. Due to their small size and ease of production, SMD 2835 chips are generally less expensive than larger, more powerful LED chips.

What is SMD 3030

SMD 3030 is a 3.0mm x 3.0mm square LED chip, a multi-chip LED package containing multiple LED chips in a single unit, arranged in a grid pattern on a substrate for better light output and efficiency. Known for its high luminous efficiency, low power consumption, and long life, SMD 3030 LEDs are commonly used in various lighting fixtures, including commercial, street light, flood light, and even residential lighting.

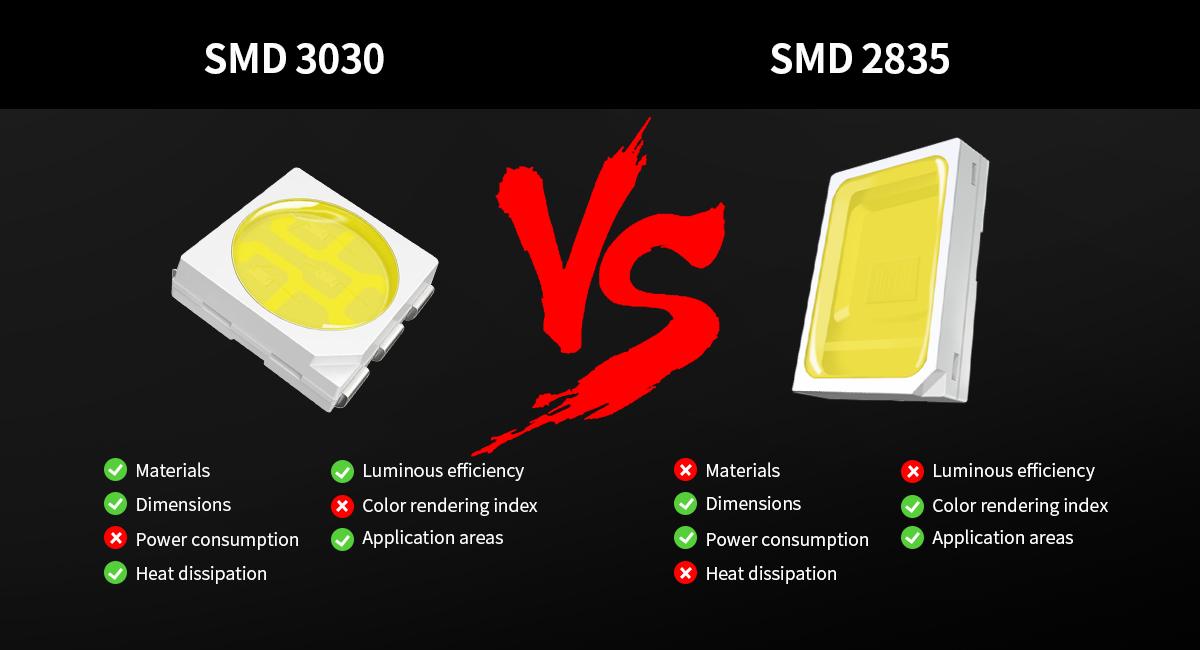

SMD 2835 VS. SMD 3030: Features and Specifications

Regarding LED lighting, the two commonly used SMD (surface mount device) types are SMD 2835 and SMD 3030. We’ll compare the features and specifications of these two SMD types to help you make an informed decision.

- Materials

The materials used in the construction of an LED patch play a vital role in its overall quality and durability. The 3030 chip uses an EMC bracket, and the 2835 uses a PCT bracket. PCT material has poor fluidity, making injection molding troublesome and requiring a traditional stamping process, while EMC brackets are produced using a die-top process, Cost advantage. On the other hand, PCT can only reach 1W, while EMC can get 3W. Therefore, the thermal conductivity/temperature resistance of the 3030 chip is better than that of the 2835 chip.

- Dimensions

The size of SMD LEDs is an important consideration, particularly with regard to installation and compatibility with existing lighting fixtures.

SMD 2835: SMD 2835 LEDs are typically rectangular in size at 2.8 mm x 3.5 mm, which is relatively small compared to other SMD types. SMD 2835 LEDs are compact and can be used flexibly in a variety of lighting applications.

SMD 3030: In comparison, the SMD 3030LED is slightly larger, measuring 3.0mm x 3.0mm square. While they may take up more space, they allow for higher power handling and better cooling.

Although the difference may seem small, it could have implications for various applications where space constraints are a consideration.

- Power consumption

SMD 2835 is known for its low power consumption. They typically operate at lower voltages and require less power than other SMD types. This makes them ideal for energy-saving lighting solutions. SMD 3030 LEDs may consume slightly more power due to their larger size and higher light output.

The reflectivity of the PCT bracket is higher than EMC. Most high-efficiency industrial and mining lughts such as 200lm/W on the market use 2835 chips.

- Luminous efficiency

Luminous efficiency refers to the amount of light output per unit of power consumed. This is an important factor to consider when evaluating LED lighting performance.

SMD 2835 has good luminous efficiency, typically around 120-150 lumens per watt (lm/W), allowing it to efficiently convert electrical energy into light. Offers quite a bit of light output for its size and power consumption.

SMD 3030 LEDs are known for their high luminous efficiency, typically around 150-180 lumens per watt (lm/W), making them more efficient than SMD 2835 LEDs at converting electrical energy into light. Their larger size makes them suitable for applications requiring brighter lighting, such as high-power LED bulbs and floodlights.

- Heat dissipation

Efficient heat dissipation is critical to the longevity and performance of LED lights. If an LED generates too much heat without proper dissipation, performance degradation, and shortened lifespan may occur. In this regard, SMD 3030 LEDs have better heat dissipation capabilities than SMD 2835 LEDs. The larger package size of SMD 3030 improves heat dissipation, helping to reduce the operating temperature of the LED and extend its service life. Due to its ceramic base, SMD 2835 can also effectively conduct heat away from the LED chip, ensuring stable performance and extending service life.

- Color rendering index

Color rendering index (CRI) is a measure of how accurately a light source displays the true color of an object compared to natural light.

SMD 2835 LED usually has a higher CRI, reaching a maximum of about 95. The conventional CRI is Ra>80, and the color tolerance is less than 5. This means they offer better color rendering capabilities. Ideal for applications requiring accurate color representation, such as retail and art galleries. SMD 3030 LEDs typically have a color rendering index (CRI) of 70 to 90.

- Application areas

Due to their compact size and low power consumption, SMD 2835 LEDs are commonly used in LED bulbs, strip lights, downlights, panel lights, and bay lighting, as well as backlighting for LCD displays, signage, and automotive lighting.

SMD 3030 LED is commonly used in high-power lighting applications such as outdoor lighting fixtures (street lights, floodlights, and industrial and mining lights), stadium lighting, industrial lighting, high bay lighting, and automotive lighting due to its higher power handling capabilities and superior efficiency and high-end commercial lighting fixtures.

Conclusion

To sum up, SMD 2835 and SMD 3030 are very different in materials, power consumption, luminous efficiency, heat dissipation, and application fields. The SMD 2835 LED is smaller and suitable for general lighting, while the SMD 3030 LED is slightly larger, more powerful, and better suited for high-power applications. Understanding their features, specifications, and differences can help you choose the right LED for your specific lighting needs. Whether for general lighting or high-power applications, the SMD 2835 and SMD 3030 provide efficient and reliable lighting solutions.

FAQs

No, SMD 2835 and SMD 3030 have different dimensions and performance characteristics, making them suitable for other applications. It is essential to choose the right SMD type for your specific lighting requirements.

SMD 2835 LEDs are generally more cost-effective than SMD 3030 LEDs due to their smaller size and lower material requirements.

Yes, both SMD 2835 and SMD 3030 LEDs can be dimmed using compatible dimming systems or controllers. However, it is essential to check the specifications of LED products to ensure their dimmability.

Yes, if your current lighting fixtures support LED retrofitting, you can upgrade them with SMD 3030 LEDs.

SMD 3030 LEDs are commonly used for outdoor lighting due to their higher brightness and efficiency. They can withstand harsh weather conditions and provide optimal illumination for outdoor spaces.