Plant lighting is one of the key factors in the development of facility agriculture. The systematic summary of light-emitting diode (LED) plant lighting fixture technology is presented.

We systematically summarize the development history and technical characteristics of light-emitting diode (LED) plant lighting technology, and analyse the role of plant lighting in home cultivation, greenhouse greenhouses, plant factories, forest plantations and other agricultural facilities.

It also analyses the application status of plant lighting fixtures in home cultivation, greenhouse greenhouses, plant factories, forest plantations and other fields, which is of certain reference value to practitioners and researchers in related fields.

Important Photobiological Parameters for Plant Lighting Fixtures

Plant lighting fixtures are devices that provide plants with the light they need. In the design of luminaires for plant lighting, photometric parameters are more precise than photometric and chromatic parameters, thus providing more accurate lighting effects. Important photobiological parameters for plant lighting fixtures include light quality, photosynthetic photon flux and photosynthetic photon flux density, light energy utilisation efficiency, plant photoperiodic response curve, photosynthesis rate and photon radiation efficiency.

Light quality

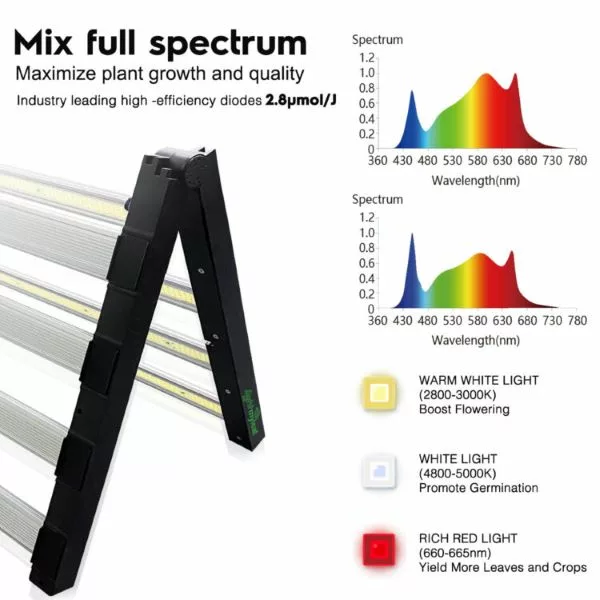

The spectral distribution of a light source is usually referred to as light quality. In practice, the light quality of plant lighting fixtures is usually expressed by the proportion of its different spectra, which is called the light quality ratio. Light of different light qualities plays different roles in plant growth. Red and orange light radiation regulates plant growth and development mainly through the response of photosensitive pigments to it. Blue and violet light radiation has a stronger effect on the chemical composition of plants and regulates photosynthesis in plant leaves and root growth and development. Chlorophyll has two strongest absorption zones for light: the red part (wavelength range of 640-660 nm) and the blue-violet part (wavelength range of 430-450 nm), and there is also an absorption zone at 700-750 nm in the red region. Therefore, compared to monochromatic light, combined light is more suitable for plant growth and development. Compared with ordinary lighting, the red and blue wavelengths of the so-called plant light lamps have a higher emissivity. The full-spectrum sunlight-like light source is very suitable for plant growth, and the research and development of this type of lamp has become one of the hot spots in the industry. one of the hotspots in the industry.

Photosynthetic photon flux and photosynthetic photon flux density

Photosynthetic photon flux (PPF) is a physical parameter describing the output capacity of a lighting device, denoted as Φp, with a unit of μmol/s. Photosynthetic photon flux density (PPFD) refers to the amount of photosynthetic photon flux per unit area of an acceptor, denoted as Φp. PPFD (photosynthetic photon flux density) is the photosynthetic photon flux received per unit area of the acceptor, denoted as Ep, and the unit is μmol -mcan be used as a reference for choosing a suitable light source and adjusting the intensity of light.

Light energy efficiency

Photosynthetic use efficiency (PUE) is a parameter that describes how efficiently light energy is used by plants, representing the ratio between the number of available photons absorbed by plants and the growth of plant biomass in g/mol. PUE is an important parameter that describes the growth rate of plants and the efficiency of light use, and can be used to evaluate the efficiency of the light source to better optimise the light strategy and improve the light quality. PUE is an important parameter describing plant growth rate and light use efficiency, and can be used to evaluate the efficiency of light sources, so as to better optimise light strategies and improve plant productivity.

Plant photoperiodic response curve

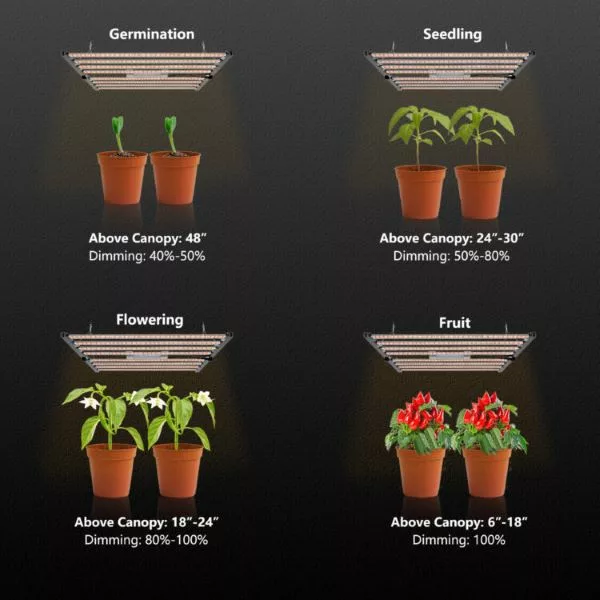

The plant photoperiod response curve describes the response of plants to different photoperiods. Generally speaking, plants are classified as long day plants, short day plants and neutral plants, and their growth and development correspond to different photoperiods. Long-day plants require longer photoperiods for their growth and development, usually more than 12 h, while short-day plants require shorter photoperiods, usually less than 12 h, and neutral plants around 12 h. This parameter is important for plant lighting fixtures to respond to different photoperiods. This parameter is very important for the design and application of plant lighting fixtures, and different photoperiods can be selected according to the type of plant and the required growth stage to promote the growth and development of the plant and increase the yield.

Rate of photosynthesis

The rate of photosynthesis is the rate per unit of time at which a plant converts carbon dioxide into organic matter through photosynthesis. Photosynthesis is an important way for plant growth and development and energy production.

Photosynthesis is an important way for plants to grow and develop and produce energy, and the level of photosynthesis rate directly affects the growth and development of plants and their yields. Therefore, the design of plant lighting fixtures needs to consider how to improve the efficiency of photosynthesis and the rate of photosynthesis. Some studies have shown that the rate of photosynthesis may be enhanced under red and blue light, while yellow-green light may lead to a decrease in the rate of photosynthesis.

Photon radiation efficiency/photon flux efficiency

Photon radiation efficiency is one of the most important indicators for evaluating plant light fixtures. The amount of radiation received by plants per day determines the cost and quality of cultivation, and plant light fixtures that meet the requirements need to be selected according to the actual situation.

In general, the above photobiological parameters are of great significance for the design and application of plant lighting fixtures. When choosing light sources, we need to consider the spectrum, light intensity, photoperiod and other factors, and combined with the needs of different plants to carry out a reasonable layout of lamps and lanterns, in order to improve the growth and development of plants and yields.

LED Plant Lighting Fixture Technology Development

LED plant growth light sources and luminaires

Light source light quality control category

LED light source has a rich variety of light colours, which can precisely control the plant light environment according to the changes of the plant growth cycle, so as to meet the different needs of plants for light at different times. At present, there are two main types of light source solutions.

(1) Combination of multiple monochromatic light sources. The common scheme is the combination of adjustable or non-adjustable red light, blue light, yellow light, green light, far-infrared light, violet light and ultraviolet light, etc., with a wavelength of about 450-730 nm.

(2) Full-spectrum programme. Full-spectrum LED light source program mainly includes 2 kinds, respectively, blue / violet chip (single wavelength) + phosphor combination (monochrome, multi-colour), as well as the use of a variety of chip composite package mode. The latter chip composite packaging scheme includes red + blue / ultraviolet, red + green + blue, white light source + other monochrome light source, etc., can be commonly used chips in accordance with the actual needs of the combination, to facilitate the dimming of the colour, the wavelength of about 400 ~ 800 nm.

LED light source characteristics

(1) Commonly used LED light source package mainly includes surface mounted devices (surface mounted devices, SMD) package (small and medium power), single power package (medium and high power), chips on board (chips on board, COB) package (multi-chip, medium and high power) and multi-chip integrated package (multi-chip, full-spectrum, high power). etc. The single package chip has universal applicability, simple spectral proportioning scheme and low cost; however, when it is used for linear plant lights, the light mixing is not uniform, the circuit design is complicated, the stimulation to the human eye is large, and the light pollution is serious.COB packaged LED light source, the spectral proportioning is scientific and reasonable, and the efficiency is high; however, the cost is high, and the circuit design and structural design are complicated. Multi-chip integrated package light source, good uniformity of light mixing, high efficiency, high power density, good uniformity; but its spectral ratio is fixed, inconvenient to adjust the SMD package LED chip.

SMD package LED chip power is generally 0.2 ~ 3 W, most manufacturers provide such goods, its power is mostly 0.2 ~ 0.9 W or 1 ~ 3 W. COB and integrated package LED chip power can reach up to 100 W. Small and medium-power LED chip can be through the aluminium substrate and the lamp body shell heat dissipation, and COB and integrated package LED requires special heat dissipation equipment, this equipment is generally used in aluminium substrate and the lamp body shell heat dissipation, this equipment is generally used in aluminium substrate and the lamp body shell heat dissipation. This equipment is generally made of aluminium heat dissipation fins, fin opening direction along the vertical direction, to facilitate air flow, conducive to heat dissipation.

Structure of LED plant lighting fixture

LED plant lighting fixtures can be divided into integral, disaggregated and combined according to the structure; according to the installation mode can be divided into suspended, ceiling and side-illuminated; according to the shape can be divided into strip, round and square. For example, strip LED plant lighting represented by straight tube, round plant lighting represented by industrial lamp, and square plant lighting represented by flat panel light. Among them, bar-shaped LED plant lighting lamps can obtain higher illumination in narrow and long areas, according to the light area and different plant light requirements can be set up in single row, double rows or multiple rows of lamp beads, different wavelengths of lamp beads can be combined and arranged, the current photon radiation efficiency of up to 3 μmol/J, and can be used for top fill light and inter-plant fill light. Round LED plant lighting lamps are generally installed vertically, can be in a larger area to obtain higher light intensity, suitable for larger space plant factories, etc., can be used in a variety of installation methods, the current photon radiation efficiency of this type of lamps and lanterns can be up to 2 μmol / J. Square LED plant lights can obtain a higher light intensity, suitable for larger plants, generally using the ceiling or ceiling mounting method, with convenient installation, flexible use of characteristics. It is easy to install and flexible to use. Square LED plant lighting lamps include 2 types, 1 type is a single square lamp, and the other type is a combination of plant lights. Single square lamps mainly include panel lights and high-power module lights, panel lights are generally composed of SMD or high-power lamp beads according to a certain red and blue ratio of multi-colour arrays; high-power module lights are generally composed of high-power chips according to a certain ratio and the regular layout of the integrated package, which can obtain a higher light intensity. Combination of plant lights can be further combined by panel lights and high-power module lights to meet the needs of plant lighting. At present, the photon radiation efficiency of this type of lamp and lanterns can reach 2.7 μmol/J.

LED plant lighting fixture design

In order to solve the problem that the traditional LED optical structure can not meet the uniformity of multi-colour LED beads, researchers have carried out a lot of work on the ratio and arrangement of LED plant lighting fixtures and secondary optical design.

The ratio, distance and arrangement of LED beads are important factors affecting the light uniformity and intensity distribution of LED plant lighting fixtures. Liang Yiqian et al. optimised the design of red and blue LED array light source, through the comparison of four different LED array layout, found that the staggered distribution of the array is conducive to improve the spectral uniformity of the light source array. Jiao Feiyu et al. proposed a plant light source system with high illumination uniformity for LED plant light sources. Ming Zhenxing et al. proposed an array arrangement such as square matrix to improve the illumination uniformity. Array arrangement of LED plant lighting beads only, the light

There is not enough distance for coupling, which will result in affecting the uniformity of light. If light spots appear on the close illuminated surface, the balanced growth of the plant is affected. Therefore, the secondary optical design of LED plant lighting fixtures is very necessary. Jin Xiaolin et al, Zhang Shuai et al, Lai Liping et al, respectively, designed the addition of multiple lamps and fibre optic lenses, prismatic light-mixing elements, scalar lenses and other programs, so that the uniformity of light reached 90%, 91%, 93%, respectively. In recent years, researchers have continued to design the optical structure of LED plant lighting fixtures to ensure the light efficiency of the system, but also to improve the light uniformity of the system. Chen Haowei et al. designed an LED plant group cultivation lamp with a free-form base plate structure, and its light uniformity is about 80%. Lu Yunle et al. studied the design of a plant culture frame with inverted light source, placing the LED lamp beads on the curved reflective top surface to further distribute the light emitted by the LEDs uniformly, with an illumination uniformity of 91.64% and a colour mixing uniformity of 89.73%.

LED plant lighting control system

The sum of plants' demand for light quality, photoperiod, light intensity, and light mode is called light formula in the industry. Simple, fixed red and blue LED beads combination, it is difficult to meet the growth of different plants or the same plant at different stages of growth of a variety of light needs, the need for accurate control of the light environment according to the growth of plants. JU Hongyan et al. designed a miniature plant factory LED multi-spectral light supplement system, which can control 25 different wavelengths of lamps to achieve the free fitting of LED spectra. Cheng et al. designed a kind of LED plant light that can dynamically adjust the light intensity, photoperiod and light quality, so that the relevant parameters of LED plant light can be adjusted in real time according to the different growth needs of plants. Large-area plant replenishment is systematic, and the adjustment of plants should be made according to the plants themselves and their growing environment. The light replenishment system needs to work together with other control systems such as circulation system, and with the development of science and technology and the wide application of computers, the intelligent control system is gradually mature. The optimisation algorithm model designed by Liu Xiang can improve the efficiency of facility light environment detection and intelligent regulation system. Zhang Haihui et al. developed a plant adaptive and precise light replenishment system, which greatly improved the light energy utilisation by precisely regulating the amount of sub-wavelength replenishment. Bao et al. designed an LED plant lighting system, data acquisition and remote management system based on wireless network communication technology, which can intelligently regulate the lighting situation during planting.

Application Scenarios

Home cultivation

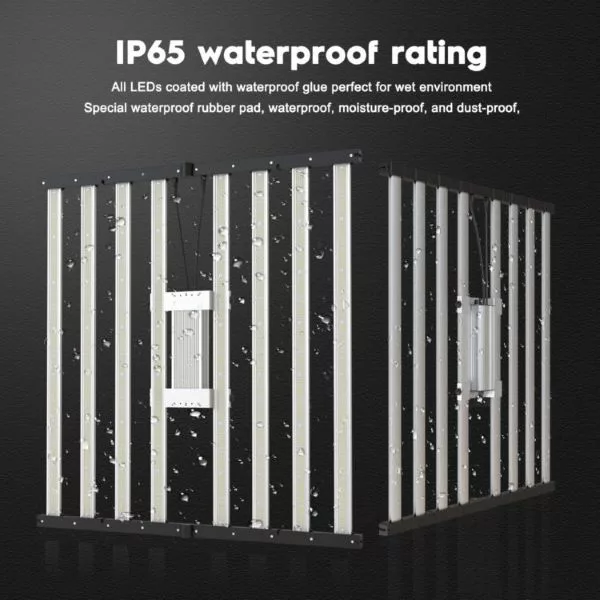

Home vegetable cultivation meets the consumer demand for vegetables with high freshness and variety [18]. It is generally a combination of soilless cultivation and hydroponics, and includes a series of automated control systems such as light replenishment system, control system, supply system and irrigation system in the design of the device, which can achieve the real-time adjustment of the overall external environment required for plant growth and ensure the normal growth of plants.

Greenhouse

The use of intelligent LED fill light system, control of LED fill light intensity and light spectrum and other related parameters, can achieve accurate fill light for greenhouse greenhouse [20]. Through the monitoring module and the central intelligent control module, the modern information and communication system is organically combined with the replenishment system, and the intelligent replenishment system of the greenhouse greenhouse can maximize the cost savings and obtain the maximum economic benefits through the adjustment of the light intensity and light spectrum.

Plant factory

Plant factory is one of the modern new forms of efficient agriculture, which can precisely regulate water, light, temperature, gas and fertiliser, etc., and improve the efficiency and quality of crop cultivation by replacing the unstable agricultural environment. A standard model of relevant light formula and environmental formula can be obtained through experiments on the plant growth process, and then computer technology can be used to establish a centralised and unified service model.

Understorey cultivation

The heterogeneity of understorey light environment can effectively protect the diversity of understorey plants. In Xishuangbanna, Yunnan, the "plant light supplement system" under the rubber forest has greatly improved the quality of local rubber, increased the income of rubber farmers, and transformed the original single-species rubber forest in Xishuangbanna into a species-rich planting base. Through the study on the key factors of maintaining the species diversity of understorey vegetation in Qinghai, it is found that the heterogeneity of understorey light environment can directly affect the species composition and diversity of understorey plants.

Conclusion

LED lamps can meet the various needs in the field of plant lighting by precisely regulating the light quality, light intensity and photoperiod in accordance with the production cycle of plants and changes in external light. With the development of light technology

With the development of light technology and the deepening and expanding of photobiology, plant lighting technology is expected to be further closely integrated with ecological protection and ecological restoration technology, which has a broad prospect.